PADMINI INNOVATIVE MARKETING SOLUTIONS PVT. LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PADMINI INNOVATIVE MARKETING SOLUTIONS PVT. LTD.

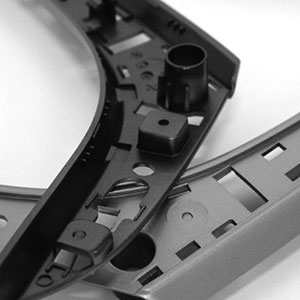

Polybutylene Terephthalate (Pbt)

52632.jpg)

Features:

PBT blend is engineering plastics

Good creep resistance, very hard ,rigid and strong

High heat-distortion temperature, especially for glass fiber-reinforced grades

Service temperature to 140°C

Very good low-friction and wear-resistant properties

High dimensional stability (low thermal expansion coefficient, low water absorption)

Good electrical properties

Good chemical resistance

No environmental stress cracking

Good weathering resistance

Rapid crystallization and fast cycle time

Paintable

Flame-retardant grades available (UL 94 V-0, in some cases 5VA)

Applications:

Automotive (gear, sensor connectors)

Electrical and Electronics (lamp sockets, connectors, electrometrical components)

Consumer goods (handles and covers of cookers, electrical iron, casing for sandwich toaster)

Fibers in toothbrushes

It is used in the keycaps of some mechanical keyboards

Fluid handling

Medical and pharma (inhaler components, drug delivery systems, and aerosol valves)

Packing, film, printing

Personal care and cosmetics

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

52563.jpg)

52568.jpg)

52571.jpg)

52572.jpg)

52575.jpg)